-

- Screw Air EndThis solution is the best possible way to build a reliable, compact and cost efficient complete compressor package with ultimate efficiency, low noise and the highest quality standards.View Products

-

- Rotary Screw CompressorThe unique design of the air compressor provides greater energy efficiency and higher stability, which are certified in accordance with ISO, TUV, GA and SGS standards.View Products

-

- Oil-free CompressorThese ISO 8573-1 Class 0 certified oil-free screw compressors are more reliable and energy efficient due to the patented unique design to deliver 100% oil-free air for sustainable energy savings. View Products

Compressed Air Filter

Compressed Air Filter

- Max. working pressure: 20 bar (290psi)

- Working temperature: 1.5-85°C (35-190°F)

- Filtration accuracy: 0.01ppm

- Residual oil content: 0.01ppm

- Request a quote

- Air dryer and air filter

- Features

- Applications

- Details

- Specifications

- Less water corrosion on pipelines and reduced damage to valves, cylinders, and electronic compnents;

- Protecting filter from the contamination of bulk liquid;

- High quality of compressed air;

- Efficiently removing all types of liquid from fluids;

- Decreased operating cost;

Benefits

- Higher efficiency and reliability of compressed air filtration;

- Less prone to damage of equipment;

- Simple structure, low maintenance cost;

- Higher cost-effectiveness;

- Different filter elements for specific filtration demand;

Our compressed air filter aims at removing particles (dust and dirt), liquid water, oil vapor, taste and smell from compressed air. It is ideal for a variety of industrial applications in pharmaceutical, food processing, chemical, packaging, control & instrumentation engineering to ensure higher productivity with minimal failure rate.

Compressed air filter housing The compressed air filter housings are manufactured with die-cast aluminum for robust structure with long service life. All housings are cleaned, degreased and anti-corrosion treated prior to surface coating for enhanced durability.

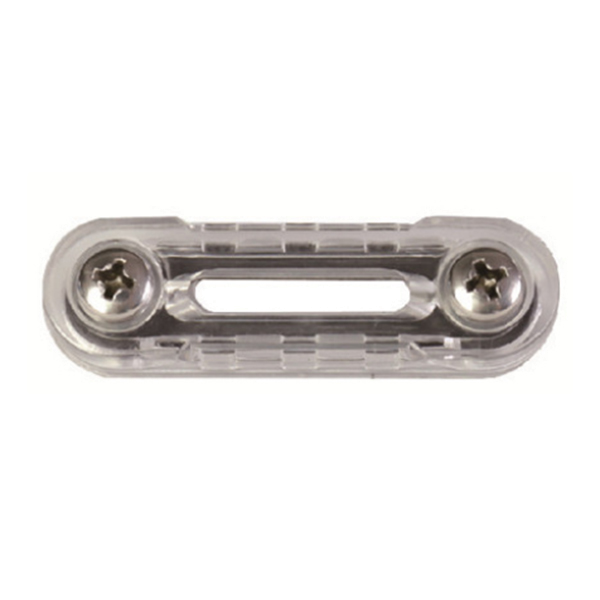

Filter element Filter element adopts push-fit method to secure the filter element without the need for tie rod, saving more space and allowing for quick and easy to install.

Leak detection system Compressed air filter leaks are very costly and difficult to find. Our leak testing system can help locate leaks that are hard to detect.

Advanced testing equipment Our laboratory is equipped advanced testing equipment introduced from Germany to ensure that all the products are compliant with the requirements of ISO8573-1:2015(E), TUV, CE and other international standards.

Differential pressure gauge This compressed air filter comes with differential pressure gauge or differential pressure indicator to simply measure the pressure difference and show the difference in pressure caused by the filter element being blocked.

Liquid level indicator As a core part of the precision filter, liquid level indicator is used to illustrate whether the liquid drain unit is blocked or not, protecting the downstream equipment from being contaminated.

Ball valve The ball valve is uniqually designed with O-ring seal, eliminating the need for thread sealing tape, providing easy installation.

Serial connection of filters Serial connection is available for easy installation of compressed air filters in series to meet more applications needs, suitable for experiments, laser cutting, spray coating, bottle blowing, etc.

| Model | Capacity (m3/min) | Air Connection | Dimension (L×W×H) | Weight | Matching compressor |

HDR-015 | 1.5 | G1/2” | 105×76×250 | 2 | 7.5KW |

HDR-024 | 2.4 | G1/2” | 105×76×250 | 2 | 11kw |

HDR-035 | 3.5 | G3/4” | 105×76×250 | 3 | 15kw/18.5kw |

HDR-060 | 6 | G1” | 105×76×250 | 4 | 22kw/30kw |

HDR-090 | 9 | G1-1/2” | 105×76×310 | 5 | 37kw/45kw |

HDR-120 | 12 | G1-1/2” | 137×99×400 | 10 | 55kw/75kw |

HDR-150 | 15 | G1-1/2” | 137×108×750 | 12 | 90KW |

HDR-200 | 20 | G2” | 148×125×920 | 13 | 110kw/132kw |

HDR-240 | 24 | G2” | 1355×135×1113 | 15 | 160kw |

HDR-360 | 36 | DN150 | 475×135×1265 | 137 | 185KW/200KW |

HDR-450 | 45 | DN150 | 475×175×1315 | 140 | 250KW |

HDR-600 | 60 | DN150 | 525×175×1315 | 180 | 315KW |

HDR-900 | 90 | DN200 | 590×175×1350 | 200 | 355kw/400kw |

HDR-1200 | 120 | DN250 | 660×175×1350 | 250 | 450/500KW |

HDR-1500 | 150 | DN300 | 700×189×1350 | 265 | 560/600KW |

HDR-1800 | 180 | DN350 | 980×235×1350 | 300 | 650/750KW |

Shanghai Rotorcomp is dedicated to provide customers worldwide with our high quality compressed air systems, which can be extensively used in machinery, medical, electronics, textile, automotive, mining, construction, and many other industries. Since the day of our establishment, we have delivered our products and services to global customers in more than 60 countries and regions.